THE SERIES SUPERCOMBINATA

SC1

from Ø 42mm to Ø 400mm (1,65 “- 15,75”)

Power Supply

Power Rated @ 110v or 230v – 50/60Hz

PORTABLE LINE BORING & ROTARY WELDING MACHINES

LINE BORING AND INTERNAL AND EXTERNAL OVERLAY WELDING, FLANGE FACING AND MACHINING OF SEATS FOR SEEGER RINGS, EXTERNAL TURNING

THE SERIES SUPERCOMBINATA

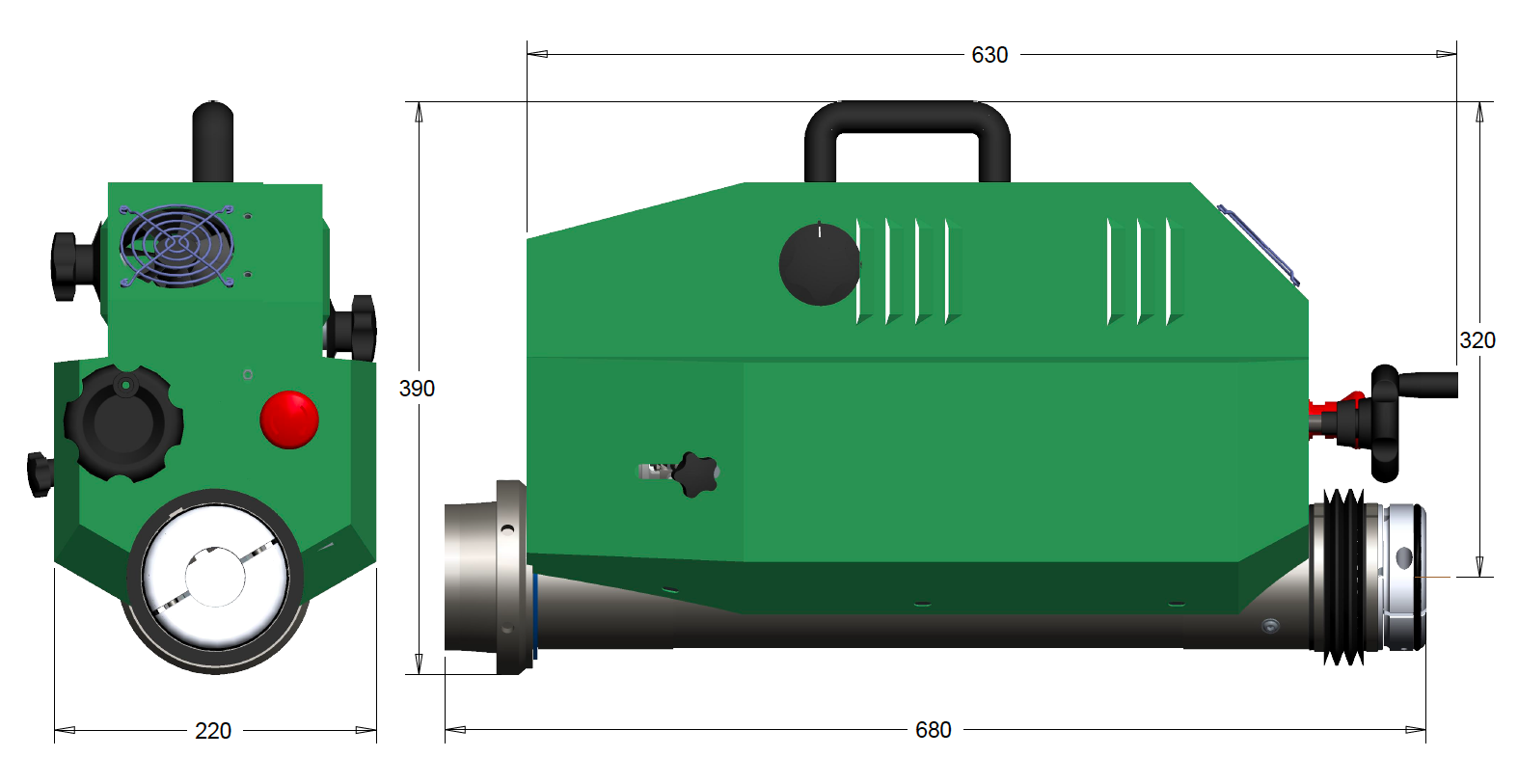

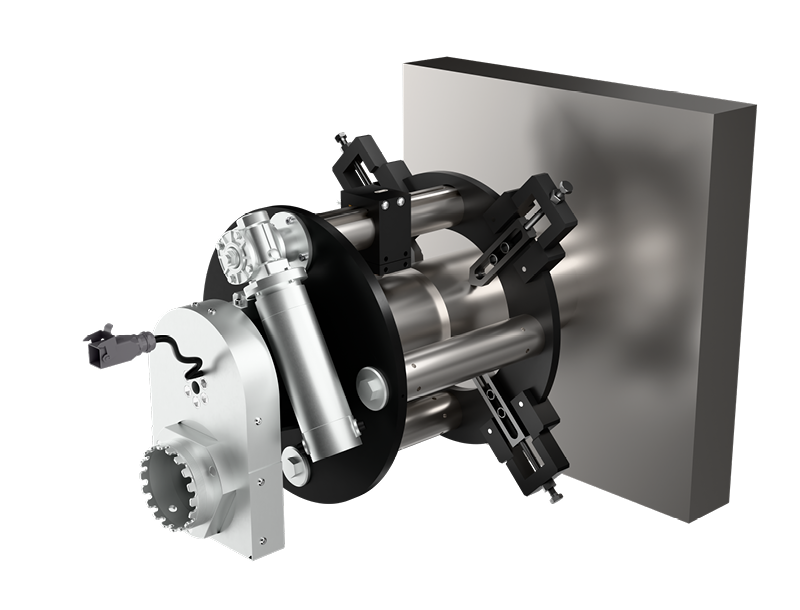

The Supercombinata SC1, with its standard equipment, is suitable to perform line boring and internal and external overlay welding within a working range from Ø 42 mm to Ø 400 mm (also blind holes). It’s suitable for drilling and tapping. By means of extra kits, it is suitable to perform external turning, facing of orthogonal planes and creation of circlips grooves, threading. With additional accessories, the Supercombinata can be adapted to many different needs of our customers. Available with a control panel for 230V or 110V power supply as well as in digital version (discover the differences).

Technical specifications

DIAMETERS

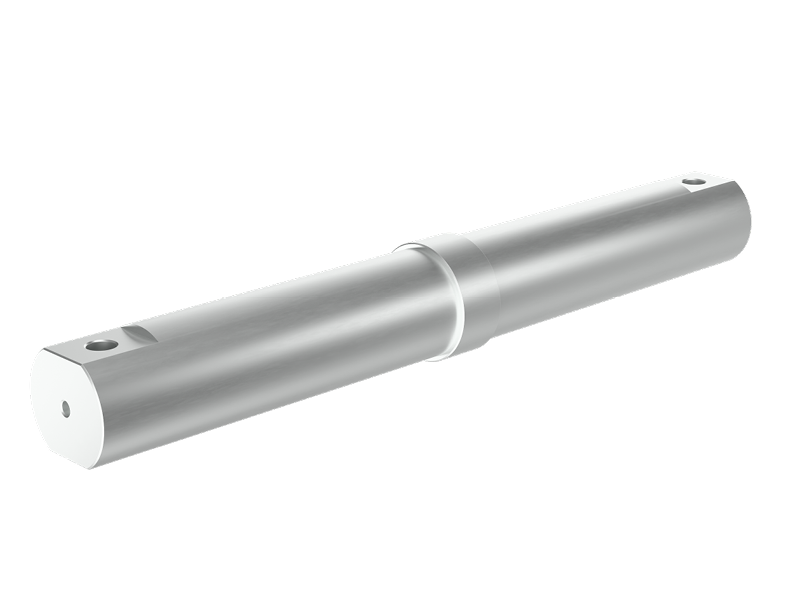

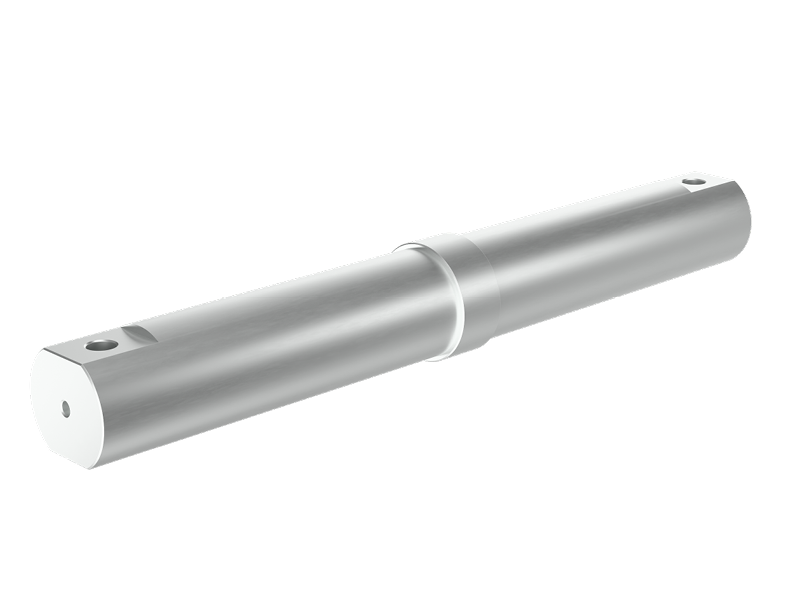

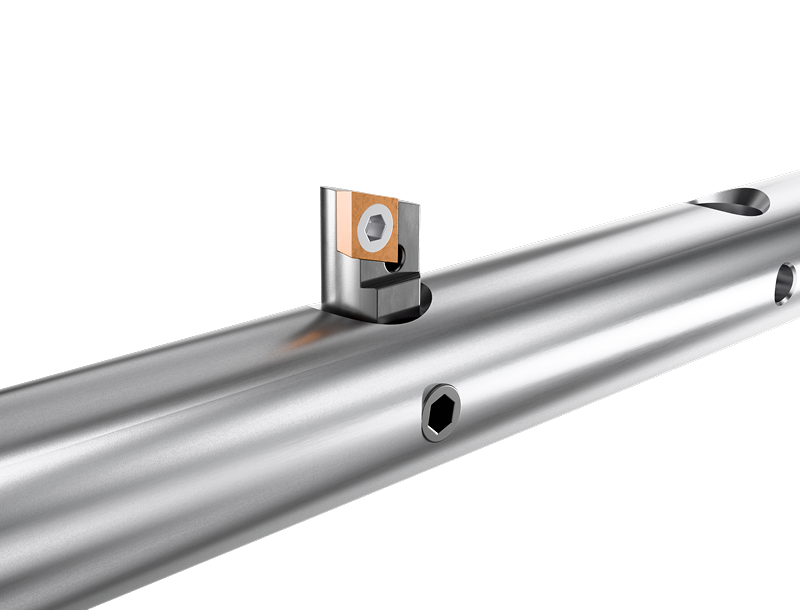

| Boring Bar Diameter: | ø 40 x 2200 mm |

| Line Boring From: | ø 42 – 400 mm |

| External Machining: | Extra kit |

| Internal Welding: | ø 42 – 400 mm |

| External welding: |

ø 42 – 400 mm |

| Drilling: | MT 4 |

| Tapping: | MT 4 |

| Threading: | Extra Kit |

| Flange Facing: | Extra kit |

ROTATION MOTOR

| AC Motor: | Single phase |

| Power Rated @: | 1800 W |

| Torque Output @ Bar: | 400 Nm @ 95 rpm |

| Transmission: | 4 Speed Gear Box |

DIMENSIONS

| Length: | 680mm |

| Width: | 240 mm |

| Height: | 380 mm |

| Machine Weight: | 36 Kg |

FEED MOTOR

| Gear Motor: | DC |

| Power Rated @: | 90W |

| Max Speed: | 11 rpm |

| Feed System: | Electromechanical |

| Feed: | Manual/Automatic |

LONGITUDINAL STROKE

| Unlimited: | With 300 mm Pitch |

ELECTRONIC CONTROL PANEL

| Voltage: | 110 or 230 V (50/60Hz) |

| Main switch: | Yes |

| Emergency Stop: | Yes |

| Feed Conrol: | RH/LH – Fwd/Rev |

| Rotation Control: | CW/CCW |

| Speed Control: | Rotation/Feed |

| Electrical Absorption: | 2000 W |

WELDING TECHNOLOGY

| Spiral: | Continuous with variable speed |

| Welding Set: | Compatibile with any MIG/MAG Wirefeeder |

| Synchronous Welding: | A given feed rate calculates rotation speed. |

STANDARD EQUIPMENT

Guaranteed Quality

2 Years Mechanical Warranty

LBW is confident in supplying quality products, hence offering our valued clients a manufacturer’s warranty of 2 years mechanical warranty and 1 year control panel warranty.

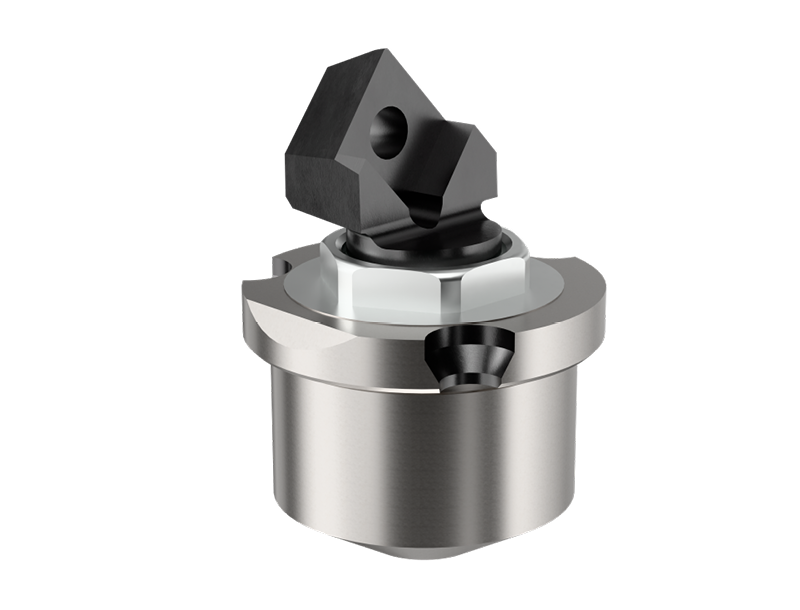

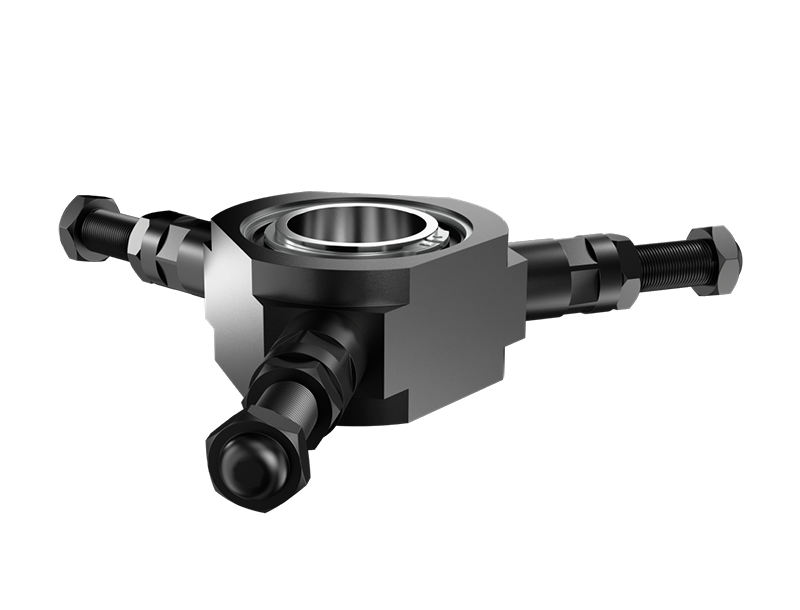

EXTRA KITS

Our additional Extra Kits are designed to give great

versatility of use to the portable line boring machines.

In turn the kits offers our clients more scope out in the field.

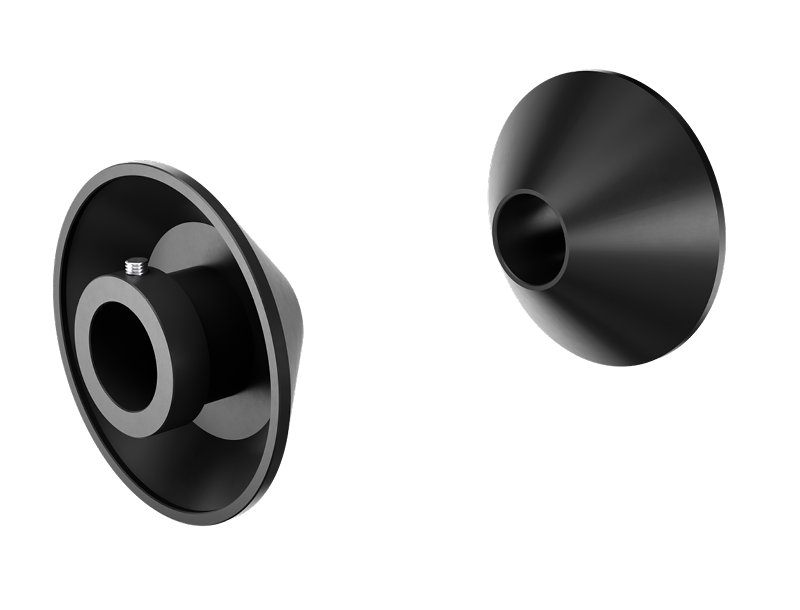

BORING REDUCTION

Ø 22 – 160 mm (0,87″ – 6,30″)

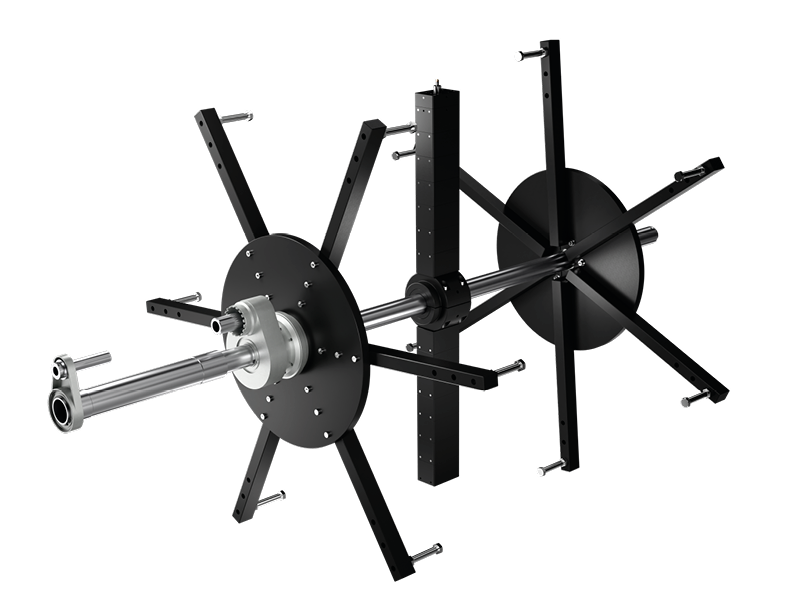

BIG DIAMETERS

Ø 400 – 1700 mm (15,75″- 66,93″)

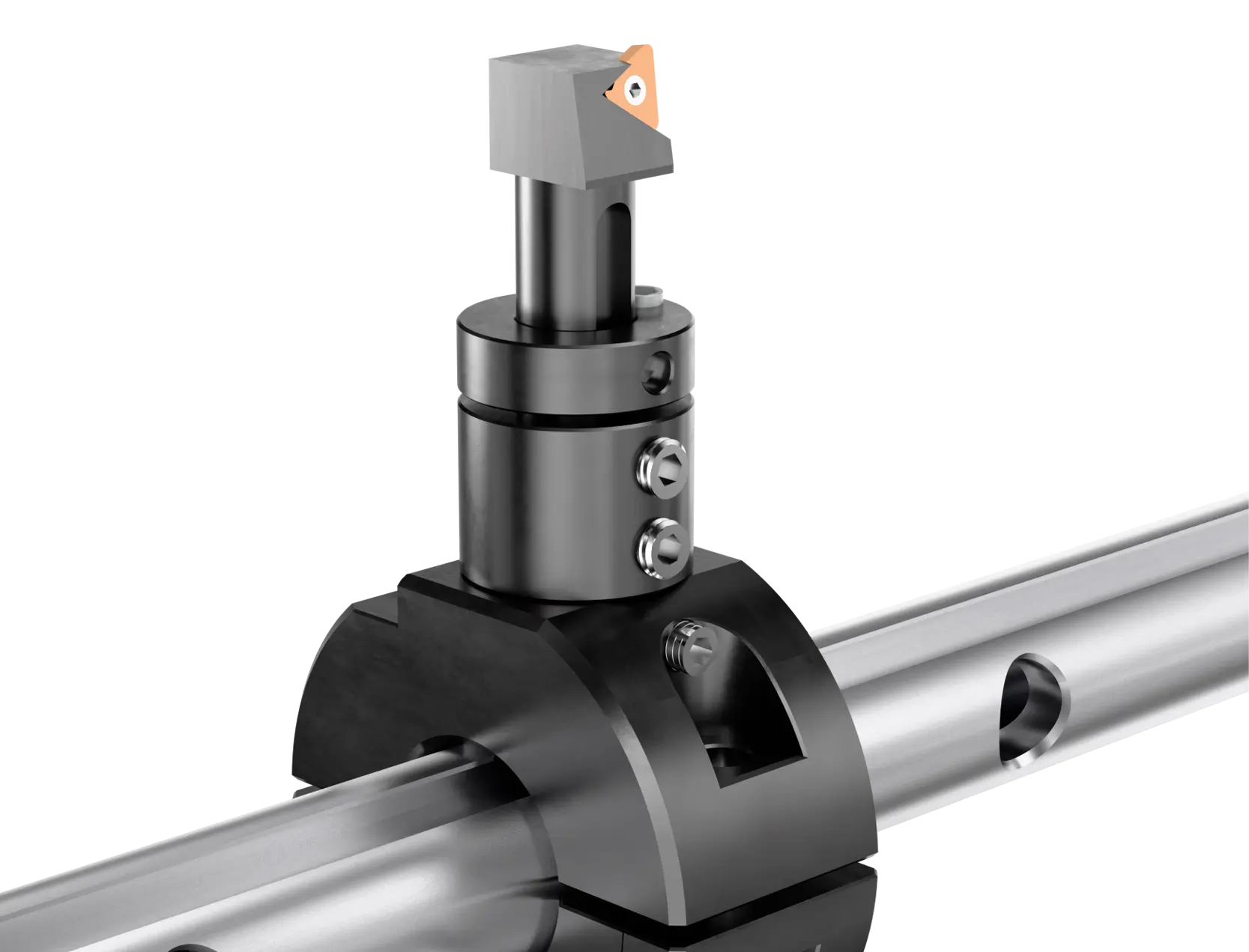

EXTERNAL TURNING

Ø 60 – 300 mm (2,36” – 11,81”)

FLANGE FACING

Ø 48 – 800 mm (1,89″- 31,50″)

INTERNAL THREADING

Ø 120 – 350 mm (4,72″ – 13,78″)

ACCESSORIES

We offer a wide range of Accessories Kits, equipping the machine,

according your needs.